Extruded aluminum siding is a popular choice in modern construction, offering a combination of durability, aesthetic appeal, and low maintenance. This material has gained widespread use in both residential and commercial buildings due to its ability to withstand harsh weather conditions, resist corrosion, and provide a sleek, contemporary look. This article provides an in-depth exploration of extruded aluminum siding, covering aluminum siding fabrication process, benefits, applications, environmental impact, and considerations for installation and maintenance.

What is Extruded Aluminum Siding?

Extruded aluminum siding is a type of building cladding made from aluminum that has been processed through extrusion. Extrusion is a manufacturing process where aluminum billets are heated and forced through a die to create long sections with a consistent cross-sectional profile. These sections are then cut, treated, and finished to be used as siding on buildings.

The extrusion process allows for a wide range of shapes and profiles, enabling manufacturers to produce siding with various textures, patterns, and finishes. This versatility, combined with the inherent properties of aluminum, makes extruded aluminum siding a preferred option for architects and builders seeking a durable and attractive exterior finish.

The Fabrication Process of Extruded Aluminum Siding

The production of extruded aluminum siding involves several stages, from raw material preparation to finishing. Each step is crucial in ensuring the final product meets the required specifications for strength, durability, and aesthetics.

1. Raw Material Preparation

The process begins with the preparation of raw aluminum, typically in the form of billets. Aluminum billets are solid cylindrical blocks of aluminum that are used as the starting material for extrusion. These billets are produced from pure aluminum or aluminum alloys, depending on the desired properties of the final product.

2. Heating the Billets

The aluminum billets are heated to a specific temperature, usually between 750°F and 900°F (400°C to 500°C). This softens the aluminum, making it malleable enough to be extruded without cracking or breaking. The temperature must be carefully controlled to ensure the material remains within the optimal range for extrusion.

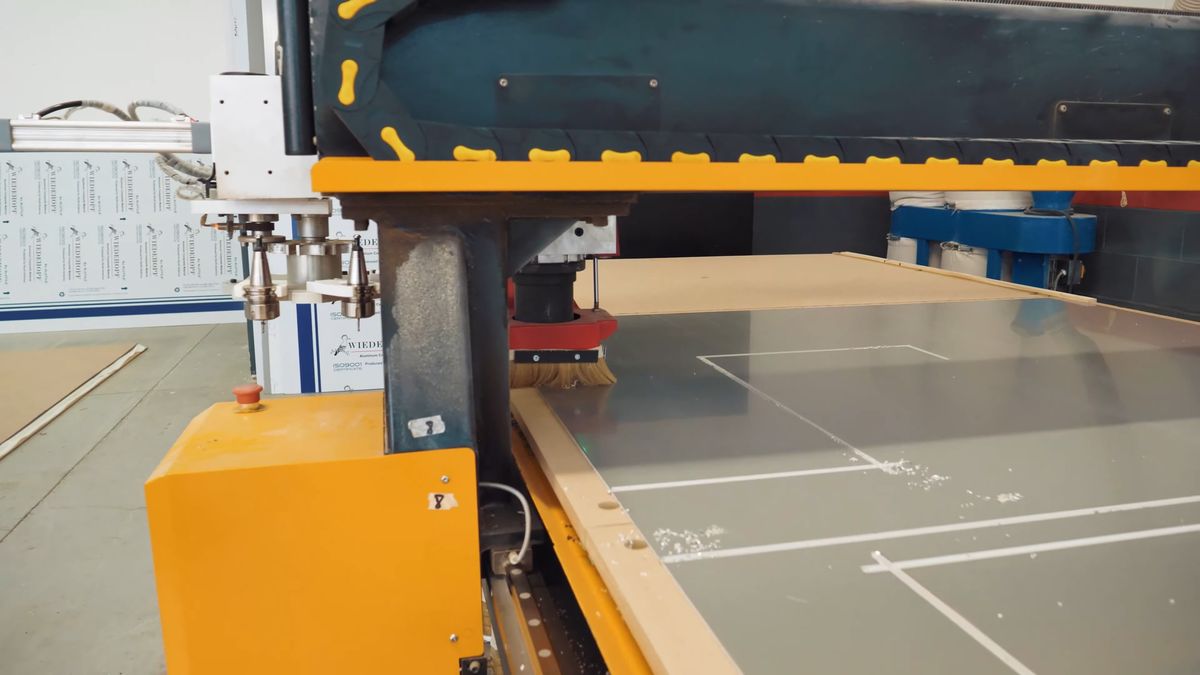

3. Extrusion Process

Once heated, the aluminum billet is placed into an extrusion press. The press applies immense pressure, forcing the aluminum through a specially designed die. The die is a tool that shapes the aluminum as it is extruded, determining the cross-sectional profile of the siding.

As the aluminum is pushed through the die, it emerges as a long, continuous piece with the desired shape. This extruded aluminum is then cut into manageable lengths, typically ranging from 12 to 24 feet, depending on the specific application.

4. Cooling and Straightening

After extrusion, the aluminum sections are cooled, typically using air or water. Cooling is a critical step, as it helps to solidify the material and stabilize its dimensions. Once cooled, the extruded sections may undergo straightening to correct any minor distortions that occurred during extrusion.

5. Surface Treatment

The next step involves treating the surface of the aluminum siding to enhance its appearance and performance. Common treatments include:

- Anodizing: This electrochemical process increases the thickness of the natural oxide layer on the aluminum surface, providing enhanced corrosion resistance and the ability to apply various colors.

- Powder Coating: A dry powder is applied to the surface of the aluminum and then cured under heat, forming a durable, protective layer. Powder coating offers a wide range of color options and is highly resistant to chipping, fading, and scratching.

- Painting: Traditional wet paint can also be applied to aluminum siding, allowing for custom colors and finishes. High-quality paints used in this process are designed to withstand UV exposure and harsh weather conditions.

6. Cutting and Shaping

After surface treatment, the extruded aluminum sections are cut to their final lengths and, if necessary, shaped into specific profiles. This may include creating interlocking edges or adding perforations for ventilation or aesthetic purposes.

7. Packaging and Distribution

Finally, the finished aluminum siding is carefully packaged to prevent damage during transportation and storage. It is then distributed to suppliers, contractors, and builders for installation on buildings.

Benefits of Extruded Aluminum Siding

Extruded aluminum siding offers several advantages that make it a popular choice in construction:

1. Durability

One of the primary benefits of aluminum siding is its exceptional durability. Aluminum is resistant to rust and corrosion, making it an ideal choice for buildings exposed to harsh weather conditions, including rain, snow, and saltwater environments. It also does not warp, crack, or swell, which are common issues with traditional wood siding.

2. Low Maintenance

Aluminum siding requires minimal maintenance compared to other materials. It does not need to be painted or stained regularly, and it can be easily cleaned with water and mild detergent. The durable finishes applied during manufacturing, such as anodizing or powder coating, help maintain the siding’s appearance over time, reducing the need for repairs or replacements.

3. Energy Efficiency

Aluminum siding can contribute to the energy efficiency of a building. When properly insulated, it helps reduce heat transfer, keeping interiors cooler in the summer and warmer in the winter. Additionally, the reflective properties of aluminum can reduce the amount of heat absorbed by the building, lowering cooling costs in hot climates.

4. Fire Resistance

Aluminum is non-combustible, meaning it does not burn or contribute to the spread of fire. This property makes extruded aluminum siding a safer choice for buildings in areas prone to wildfires or other fire hazards.

5. Aesthetic Versatility

The extrusion process allows for a wide range of profiles, textures, and finishes, enabling architects and designers to achieve various aesthetic effects. Aluminum siding can mimic the appearance of wood, stone, or other materials while offering the benefits of metal. The availability of different colors and finishes allows for customization to match any architectural style.

6. Sustainability

Aluminum is one of the most sustainable building materials available. It is 100% recyclable, and the recycling process requires only a fraction of the energy needed to produce new aluminum. This reduces the environmental impact of aluminum siding, making it an eco-friendly choice for green building projects.

Applications of Extruded Aluminum Siding

Extruded aluminum siding is used in a variety of applications across residential, commercial, and industrial buildings. Its versatility and durability make it suitable for many different types of structures:

1. Residential Buildings

In residential construction, aluminum siding is commonly used for exterior cladding. It provides a modern, sleek appearance while offering protection against the elements. Homeowners appreciate the low maintenance requirements and the wide range of design options available. Aluminum siding is often chosen for coastal homes due to its resistance to corrosion from saltwater.

2. Commercial Buildings

Commercial buildings, including office complexes, retail stores, and hotels, often use extruded aluminum siding for its aesthetic appeal and durability. The material’s ability to withstand heavy use and exposure to pollution makes it ideal for urban environments. Additionally, the fire-resistant properties of aluminum provide an added layer of safety for commercial structures.

3. Industrial Facilities

In industrial settings, where buildings are exposed to harsh conditions such as chemicals, moisture, and extreme temperatures, extruded aluminum siding offers a reliable solution. Its resistance to corrosion and fire makes it suitable for factories, warehouses, and other industrial facilities.

4. Architectural Features

Beyond standard siding applications, extruded aluminum is also used in architectural features such as louvers, sunshades, and decorative facades. These elements not only enhance the visual appeal of a building but also contribute to energy efficiency by controlling sunlight and reducing heat gain.

Environmental Impact and Sustainability

Extruded aluminum siding is recognized for its positive environmental impact, particularly in the context of sustainable construction practices.

1. Recyclability

Aluminum is one of the most recyclable materials in the construction industry. It can be recycled repeatedly without losing its quality, making it a highly sustainable option. The recycling process for aluminum uses only about 5% of the energy required to produce new aluminum from raw materials, significantly reducing the carbon footprint associated with its production.

2. Energy Efficiency in Production

The energy required to produce extruded aluminum siding has decreased over the years due to advancements in manufacturing technology and the use of recycled aluminum. This has further enhanced the sustainability of aluminum siding, making it an attractive option for environmentally conscious builders and homeowners.

3. Contribution to LEED Certification

Buildings using extruded aluminum siding can contribute to achieving Leadership in Energy and Environmental Design (LEED) certification. LEED is a globally recognized green building certification system, and the use of sustainable materials like aluminum can earn points toward certification in categories such as materials and resources, energy and atmosphere, and sustainable sites.

Installation and Maintenance Considerations

While extruded aluminum siding is relatively easy to install and maintain, there are important considerations to ensure optimal performance and longevity.

1. Proper Installation

Proper installation is critical to the performance of aluminum siding. It is essential to follow the manufacturer’s guidelines and use the appropriate fasteners, sealants, and underlayment. The siding should be installed with allowances for expansion and contraction due to temperature changes to prevent buckling or warping.

2. Insulation and Moisture Control

To maximize energy efficiency, it is important to pair aluminum siding with proper insulation. This helps to minimize heat transfer and improve the building’s overall thermal performance. Additionally, moisture control measures, such as the installation of vapor barriers and proper ventilation, should be in place to prevent condensation and potential water damage.

3. Regular Cleaning

Although aluminum siding requires minimal maintenance, regular cleaning is recommended to remove dirt, debris, and environmental contaminants that can accumulate over time. Using a soft brush or sponge with water and mild detergent is usually sufficient. Avoid abrasive cleaners or tools that can scratch the surface.

4. Inspection for Damage

Periodic inspection of aluminum siding is important to identify any signs of damage, such as dents, scratches, or areas where the finish has worn away. Prompt repair or touch-up can prevent further deterioration and maintain the siding’s appearance and protective properties.

Conclusion

Extruded aluminum siding is a versatile, durable, and sustainable choice for modern construction. Its combination of strength, low maintenance, and aesthetic flexibility makes it suitable for a wide range of applications, from residential homes to commercial buildings and industrial facilities. The fabrication process, involving extrusion and advanced surface treatments, results in a high-quality product that can withstand the elements and contribute to energy efficiency.

As the demand for eco-friendly building materials continues to grow, extruded aluminum siding stands out as a responsible choice that meets the needs of both builders and the environment. By understanding the benefits, applications, and considerations for installation and maintenance, architects, contractors, and homeowners can make informed decisions that enhance the performance and longevity of their buildings.