Wood composite panels are engineered products made by binding wood fibers, particles, or veneers together with adhesives or other bonding methods. These materials have gained popularity across various industries, particularly in construction and furniture manufacturing, due to their versatility, cost-effectiveness, and environmental benefits. The fabrication of wood composite panels involves a series of processes, each of which is critical to ensuring the final product meets specific performance criteria. This article delves into the detailed process of fabricating wood composite panels, highlighting the materials used, the various manufacturing techniques, and the applications of these products.

Materials Used in Wood Composite Panels

The primary materials used in wood composite panels are wood fibers, wood particles, and veneers. The choice of material depends on the type of composite panel being produced.

- Wood Fibers: These are typically used in the fabrication of Medium Density Fiberboard (MDF) and High-Density Fiberboard (HDF). The fibers are derived from both hardwood and softwood, though softwood is more commonly used due to its abundance and cost-effectiveness.

- Wood Particles: These are used in the production of particleboard, a common type of wood composite panel. The particles can vary in size and shape, from large chips to fine sawdust, depending on the desired properties of the final product.

- Veneers: Thin layers of wood, known as veneers, are used in the production of plywood and laminated veneer lumber (LVL). Veneers are typically cut from logs using a rotary lathe or slicing machine.

- Adhesives and Binders: A variety of adhesives are used in the fabrication of wood composite panels. The most common are urea-formaldehyde (UF), phenol-formaldehyde (PF), and melamine-formaldehyde (MF) resins. These adhesives are chosen based on factors such as moisture resistance, strength, and curing time.

- Additives: Additional materials such as wax, preservatives, and fire retardants may be added to enhance the performance of the wood composite panels.

The Fabrication Process

The fabrication of wood composite panels involves several stages, each critical to the quality and performance of the final product. The following sections outline the key steps involved in the production of different types of wood composite panels.

1. Raw Material Preparation

The first step in the fabrication process is the preparation of raw materials. This involves reducing the wood to the desired form, whether it be fibers, particles, or veneers.

- Debarking and Chipping: Logs are first debarked to remove the outer bark. This is important as the bark can contain impurities that may affect the quality of the final product. The debarked logs are then chipped into smaller pieces.

- Fiber Preparation: For fiberboard production, wood chips are further processed into fibers. This is typically done using a refiner, where the chips are subjected to high pressure and temperature, breaking them down into individual fibers.

- Particle Sizing: In particleboard production, the wood chips are sorted and screened to ensure uniform particle size. This is important for achieving a consistent density and strength in the final product.

- Veneer Cutting: For plywood and LVL, logs are peeled or sliced to produce thin layers of wood, known as veneers. These veneers are then dried to reduce their moisture content, which is crucial for proper adhesive bonding.

2. Blending with Adhesives

Once the raw materials are prepared, they are mixed with adhesives. The type and amount of adhesive used depend on the specific requirements of the composite panel being produced.

- MDF and HDF: In the production of MDF and HDF, wood fibers are blended with a resin binder. The fibers and resin are mixed thoroughly to ensure uniform distribution of the adhesive.

- Particleboard: Wood particles are mixed with a resin binder, often in a rotating drum or blender. The particles are coated with the adhesive to ensure strong bonding during the pressing stage.

- Plywood and LVL: Veneers are coated with adhesive on both sides before they are assembled into panels. The adhesive is applied either manually or using automated spreaders, ensuring even coverage.

3. Mat Formation

After blending with adhesives, the material is formed into a mat. The mat formation process varies depending on the type of wood composite panel being produced.

- Fiberboard: The blended fibers are spread onto a conveyor belt to form a mat. The mat is typically built up in layers to achieve the desired thickness.

- Particleboard: The adhesive-coated particles are spread onto a forming line, where they are layered to create a mat. The distribution of particles is carefully controlled to ensure uniform density.

- Plywood and LVL: Veneers are stacked in layers, with each layer’s grain direction oriented perpendicular to the previous one. This cross-lamination provides strength and stability to the final product.

4. Pressing and Curing

The mat is then pressed and cured to form a solid, stable panel. This is one of the most critical steps in the fabrication process, as it determines the panel’s final density, strength, and surface quality.

- Hot Pressing: In hot pressing, the mat is subjected to high pressure and temperature, which compresses the material and cures the adhesive. The pressing time and temperature are carefully controlled to achieve the desired panel properties.

- Cold Pressing: For certain products, such as laminated veneer lumber, cold pressing is used. The veneers are pressed together at room temperature, relying on the adhesive’s natural curing process.

- Continuous Pressing: In modern production lines, continuous pressing is often used. The mat is fed through a continuous press, where it is subjected to a series of pressure and temperature zones, allowing for high-speed production.

5. Cooling and Trimming

After pressing, the panels are cooled to stabilize their dimensions and reduce internal stresses. The cooling process can take place naturally, or through the use of fans and cooling racks.

Once cooled, the panels are trimmed to their final dimensions. This involves cutting the panels to size and trimming the edges to ensure a smooth, uniform finish.

6. Sanding and Finishing

The final step in the fabrication process is sanding and finishing. This step enhances the surface quality of the panels, making them suitable for various applications.

- Sanding: The panels are sanded to achieve a smooth, even surface. This is especially important for panels used in furniture manufacturing, where surface quality is critical.

- Finishing: Depending on the intended application, the panels may undergo additional finishing processes. This can include the application of coatings, laminates, or veneers to enhance appearance and durability.

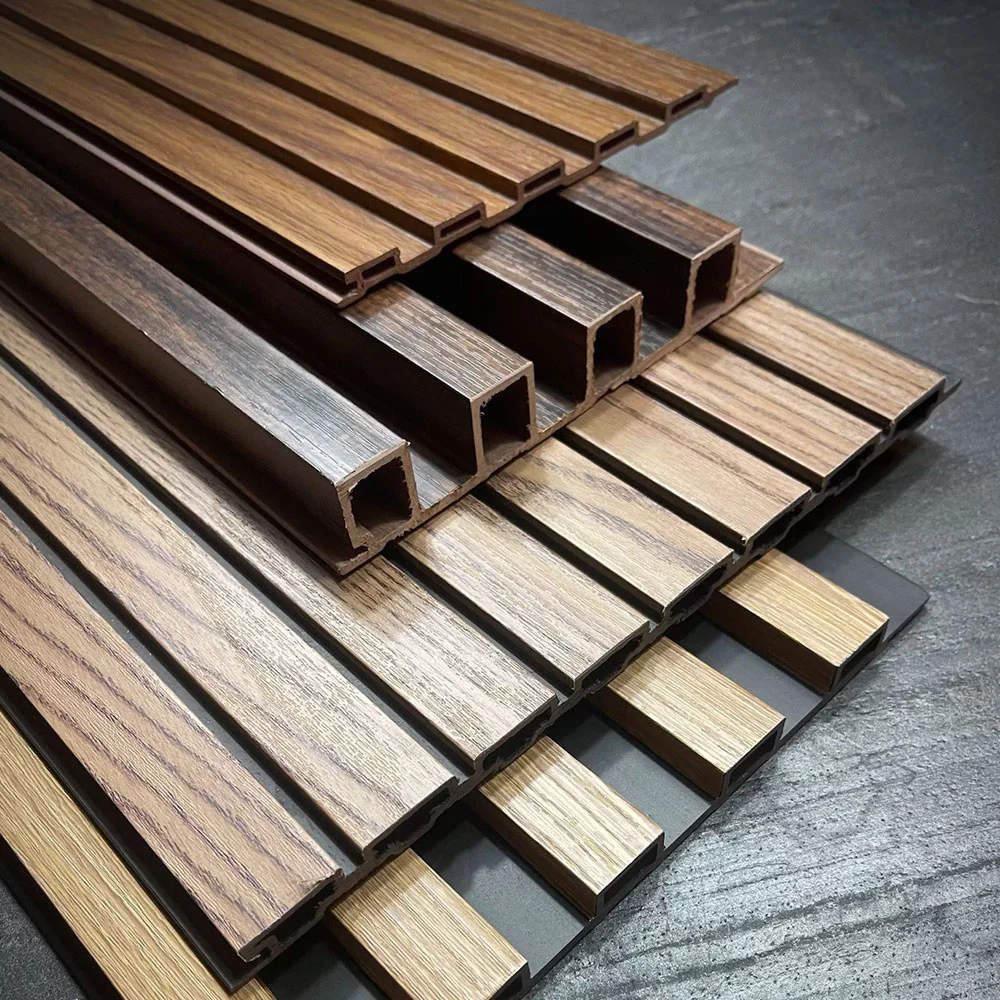

Types of Wood Composite Panels

Several types of wood composite panels are produced using the fabrication processes described above. Each type has unique properties and is suited to specific applications.

- Medium Density Fiberboard (MDF): MDF is made from wood fibers and is known for its smooth surface and uniform density. It is widely used in furniture manufacturing, cabinetry, and interior paneling.

- High-Density Fiberboard (HDF): Similar to MDF but with a higher density, HDF is used in applications requiring greater strength and durability, such as flooring and high-stress furniture components.

- Particleboard: Made from wood particles, particleboard is a cost-effective option for furniture and cabinetry. It is often used as a substrate for laminates and veneers.

- Plywood: Plywood is made from layers of veneers, with the grain direction of each layer oriented perpendicular to the previous one. This cross-lamination provides strength and stability, making plywood suitable for structural applications, furniture, and cabinetry.

- Oriented Strand Board (OSB): OSB is made from large wood strands arranged in layers, with each layer’s strands oriented in a specific direction. OSB is commonly used in construction for sheathing, subflooring, and roofing.

- Laminated Veneer Lumber (LVL): LVL is made from thin layers of veneer bonded together with adhesives. It is used in structural applications, such as beams and headers, where high strength is required.

Environmental Considerations

The fabrication of wood composite panels has significant environmental implications. One of the key benefits of these products is their efficient use of wood resources. By utilizing wood fibers, particles, and veneers, composite panels make use of materials that might otherwise be considered waste. This contributes to the conservation of forests and reduces the demand for solid wood products.

Additionally, advancements in adhesive technology have led to the development of low-emission adhesives, which reduce the release of volatile organic compounds (VOCs) during production and use. This is particularly important for indoor applications, where air quality is a concern.

Moreover, wood composite panels can be recycled or repurposed at the end of their life cycle, further reducing their environmental impact. For instance, MDF and particleboard can be broken down and used as raw material for new panels or other products.

Applications of Wood Composite Panels

Wood composite panels are used in a wide range of applications across various industries. Some of the most common uses include:

- Furniture Manufacturing: MDF, particleboard, and plywood are widely used in the production of furniture, including cabinets, shelves, and tables. Their uniform density and smooth surface make them ideal for these applications.

- Construction: Plywood, OSB, and LVL are commonly used in construction for structural applications, such as sheathing, subflooring, and beams. Their strength and stability make them suitable for load-bearing applications.

- Interior Design: MDF and particleboard are often used in interior design for wall paneling, moldings, and decorative elements. Their smooth surface allows for easy finishing with paint, veneers, or laminates.

- Flooring: HDF is commonly used as a core material for laminate flooring, providing a stable and durable base for the decorative surface layer.

Conclusion

The fabrication of wood composite panels is a complex process that involves the careful preparation of raw materials, blending with adhesives, and pressing and curing to produce high-quality products. These panels offer numerous advantages, including efficient use of wood resources, versatility, and cost-effectiveness. As demand for sustainable and affordable building materials continues to grow, wood composite panels will likely play an increasingly important role in various industries, from construction to furniture manufacturing. By understanding the fabrication process and the properties of different types of wood composite panels, manufacturers and consumers can make informed decisions that contribute to the development of more sustainable and efficient products.