Wood composite panels, a product of modern innovation, have revolutionized the construction and design industries. Combining the natural beauty of wood with enhanced durability and sustainability, these panels offer a plethora of applications across various sectors. From architectural projects to furniture manufacturing, wood composite panels have become a go-to choice for designers, architects, and builders alike.

Understanding Wood Composite Panels

Wood composite panels represent a sophisticated blend of natural materials and modern engineering. These panels are crafted from wood fibers or particles, which are bound together using adhesives under heat and pressure. The result is a versatile material that combines the aesthetic appeal of wood with enhanced durability and performance characteristics. Understanding the composition and manufacturing process of wood composite panels is essential for appreciating their wide-ranging applications across industries.

Various types of wood composite panels exist, each with distinct properties and applications. Particleboard, for instance, is made from wood particles bonded together with resin, offering a smooth and uniform surface suitable for furniture and cabinetry. Medium-density fiberboard (MDF), on the other hand, consists of fine wood fibers bonded under pressure, providing excellent dimensional stability and machinability for interior applications like paneling and trim. Plywood, another common type, comprises thin layers of wood veneer glued together in alternating grain orientations, offering strength and versatility for structural and decorative purposes.

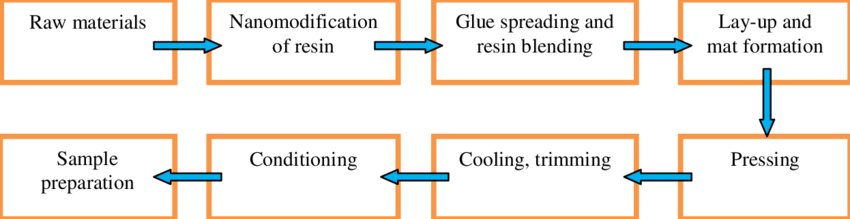

The manufacturing process of wood composite panels involves precision and control to achieve desired properties. Wood fibers or particles are first sorted and refined to specific sizes before being mixed with adhesives. The mixture is then formed into panels under high pressure and temperature, ensuring proper bonding and consolidation of the material. Advanced technologies and quality control measures are employed throughout the production process to optimize panel performance and consistency. By understanding the intricacies of manufacturing, designers and builders can confidently incorporate wood composite panels into their projects, harnessing their inherent strengths and characteristics to achieve desired outcomes.

Architectural Applications

- Cladding: Wood composite panels are extensively used for exterior cladding in both residential and commercial buildings. They offer the warmth and texture of natural wood while providing superior weather resistance and durability compared to traditional wood. Composite panels come in a range of finishes, colors, and textures, allowing architects to achieve diverse design aesthetics.

- Interior Paneling: In interior design, wood composite panels are employed for wall paneling, ceiling treatments, and decorative elements. They bring warmth and elegance to interior spaces while offering versatility in design. Additionally, composite panels can be manufactured with fire-retardant properties, making them suitable for use in public buildings where fire safety is a concern.

- Doors and Windows: Composite panels are increasingly used in the fabrication of doors and window frames. These panels provide stability and resistance to warping or twisting, ensuring long-term performance even in harsh environmental conditions. Moreover, they can be customized to match the architectural style of the building.

Furniture and Cabinetry

- Furniture Manufacturing: Wood composite panels serve as an excellent alternative to solid wood in furniture manufacturing. They are dimensionally stable, making them less prone to expansion and contraction due to humidity changes. This stability ensures that furniture made from composite panels maintains its shape and structural integrity over time. Additionally, composite panels can be laminated with veneers or laminates to achieve a variety of finishes and styles.

- Cabinetry: Kitchen cabinets, wardrobes, and storage units often utilize wood composite panels for their construction. These panels offer a smooth, uniform surface that is ideal for painting or applying finishes. Furthermore, composite panels can be machined and routed with precision, allowing for intricate designs and detailing in cabinetry.

Industrial and Transportation

- Packaging: Wood composite panels are used in the manufacturing of crates, pallets, and packaging materials. Their strength and rigidity make them suitable for safely transporting goods while minimizing the risk of damage during transit.

- Automotive Interiors: In the automotive industry, wood composite panels find applications in interior trim components such as door panels, dashboard inserts, and console accents. They provide a lightweight and cost-effective alternative to traditional materials while offering aesthetic appeal and design flexibility.

Environmental Sustainability

Wood composite panels offer a compelling story of environmental sustainability in modern industries. By utilizing wood fibers sourced from fast-growing, renewable forests, these panels reduce the pressure on natural forests, promoting responsible forestry practices. Additionally, many manufacturers employ recycled wood fibers and adhesives with low formaldehyde emissions in the production process, further minimizing environmental impact. This emphasis on sustainable sourcing and manufacturing processes ensures that wood composite panels contribute positively to environmental conservation efforts.

Furthermore, wood composite panels help mitigate the carbon footprint associated with traditional materials. Through the sequestration of carbon dioxide in wood fibers, these panels act as a carbon sink, effectively reducing greenhouse gas emissions. By choosing wood composite panels over materials with higher embodied carbon, such as concrete or steel, builders and designers can significantly lower the environmental footprint of their projects. This aspect is crucial in combating climate change and promoting a more sustainable built environment.

Moreover, wood composite panels play a role in the circular economy by facilitating the reuse and recycling of wood materials. At the end of their lifecycle, these panels can be repurposed or recycled into new products, minimizing waste and conserving resources. This closed-loop approach reduces the strain on landfill sites and promotes a more efficient use of materials. As society increasingly prioritizes circularity and resource efficiency, wood composite panels stand out as a sustainable solution that aligns with these principles, making them an integral part of environmentally conscious practices in various industries.

Conclusion

Wood composite panels have become indispensable in modern construction, design, and manufacturing industries. With their blend of natural aesthetics, durability, and sustainability, these panels offer limitless possibilities for architects, designers, and builders. From enhancing the aesthetics of architectural facades to providing functional and stylish furniture solutions, wood composite panels continue to redefine the standards of innovation and excellence in various applications. As technology advances and environmental concerns grow, the demand for wood composite panels is expected to rise, driving further innovation and development in this versatile product category.